Introduction

Cr (VI) in cement is a known sensitizing agent that can cause allergies and skin irritations in individuals handling cement, mortar, or concrete.

Cr (VI) is primarily formed during the oxidation of chromium present in certain raw materials used in cement production.

The solution lies in adding a chemical agent to the cement to reduce Cr (VI) – a soluble compound – into Cr (III) – an insoluble and non-absorbable compound – effectively eliminating its harmful effects.

Synchro®

Synchro® is an advanced solution for reducing hexavalent chromium in cement.

Synchro® also previously known as Chryso® Reductis, is designed to meet regulatory compliance while ensuring the health and safety of workers.

Cr (VI) reduction

Prioritize Health & Safety of Your Teams

Easy to Use & Store; No Dusting

Lower Logistic Costs & Carbon footprint

Chloride-free

Extends Shelf Life In Cement

Key Features & Benefits

High Reduction Efficiency

Synchro® chrome reducer family consists largely of liquid additives that effectively reduce the Hexavalent Chromium (Cr VI) content in cement, even at low dosages.

Health and Safety

- Hazard-Free Solution: We have products available which are free from hazard symbols, ensuring the safety of your team and the environment.

- Non-Carcinogenic (Group 3): All Synchro® products are non-carcinogenic (Group 3), ensuring user safety and minimizing health risks during handling.

- Skin Safety: Reduces Cr (VI) to Cr (III), an insoluble form that is not absorbed by the skin, preventing allergies and skin irritations.

Liquid Additive Advantage

Synchro® products which are in liquid form, make storage more convenient.

The key benefits include:

- Elimination of dusting issues, such as the risk of dust inhalation and irritation.

- Enhanced precision in dosing compared to powder, reducing waste.

- No additional CAPEX required for powder dosing machines.

- Reduced maintenance needs and costs.

- No additional personal protective equipment (PPE) required; standard PPE can be used for safe handling during cement additive dosing.

Chloride-Free

The chloride-free composition enhances the durability and quality of cement, preventing corrosion and improving overall performance.

Extended Shelf-Life

Provides a shelf-life of over 6 months in treated cement and up to/over 12 months depending on unique cement plant needs.

This extended shelf life ensures long-lasting cement efficacy, reduces waste, and improves operational efficiency.

Lower Dosage and Freight Costs

Synchro® products require lower dosages compared to powder forms, resulting in reduced freight costs. This makes them more economical and practical for large-scale operations.

Versatile with Minimal Impact

Using our chrome reducers in all cement types will have very little to no impact on the performance and quality of the finished cement.

Cr(VI) Control Simplified with Synchro® Technology

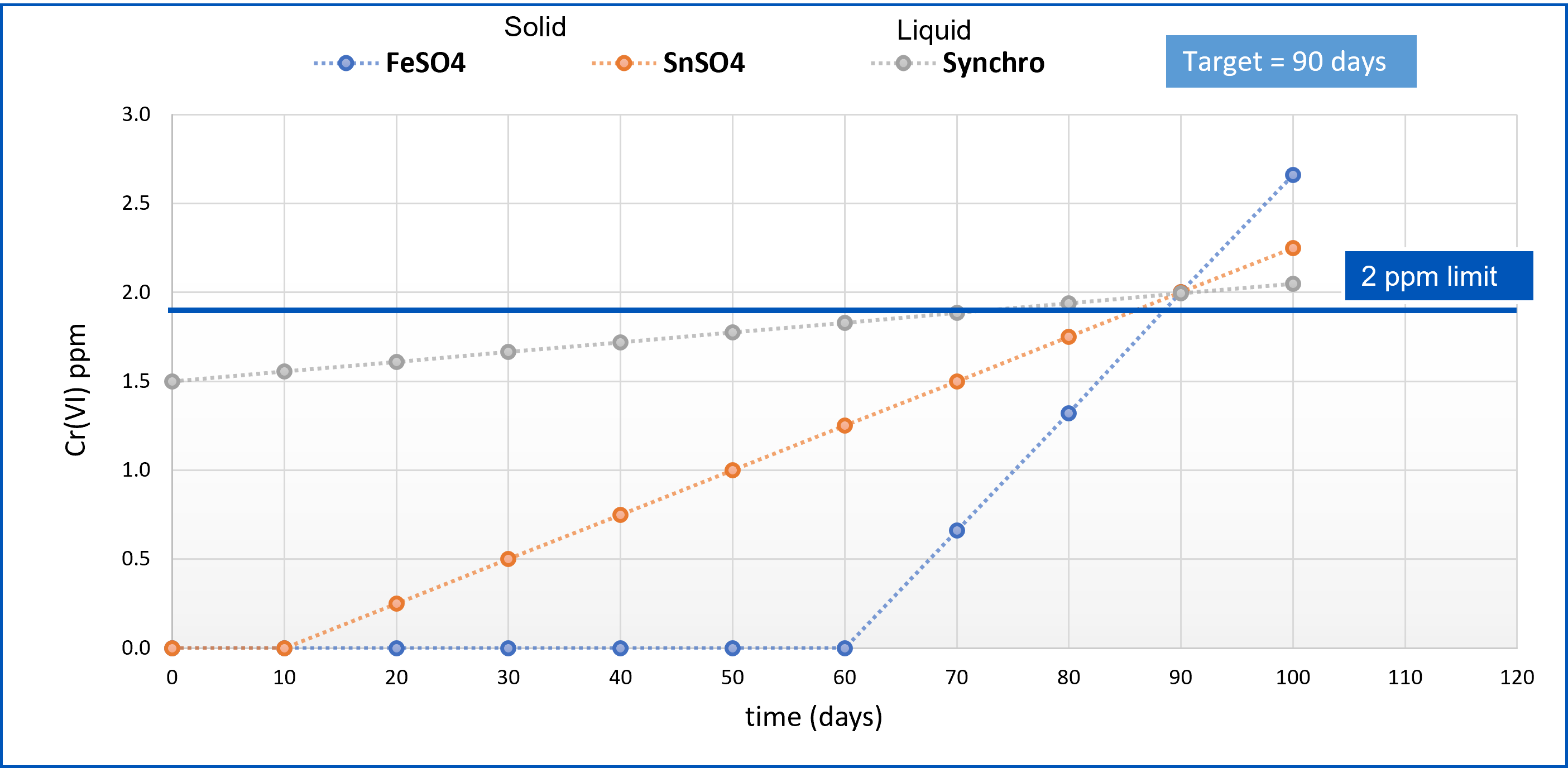

Traditional solutions like FeSO₄ and SnSO₄ struggle to maintain Cr(VI) levels below 2ppm over time:

- FeSO₄: Requires high initial doses and fails after ~60 days, with Cr(VI) levels exceeding the 2ppm limit.

- SnSO₄: Performs slightly better but still surpasses the limit by ~90 days.

Synchro® Technology demonstrates a more gradual slope, ensuring:

- Lower Dosage Needs: Effective even with higher initial Cr(VI) levels.

- Sustained Performance: Maintains levels below 2ppm throughout and beyond 90 days.

- Reliable Results: Ensures consistent, long-term compliance without operational risks.

Our Products

Synchro® 200 is a patented liquid cement additive technology for chromium reduction that also provides a shelf-life exceeding 6 months in treated cement.

Synchro® 250 is a patented liquid cement additive technology for chromium reduction that also provides up to 6 months of shelf life in treated cement.

Synchro® 300 is an innovative liquid cement additive that introduces a chromium reduction solution to the market without hazard symbols and is not classified as a “dangerous good” for transportation purposes. It provides an excellent shelf life in treated cement, exceeding 12 months.